Cooling Monitoring

Docksters partner UniCool measures the temperature and other parameters of their customers' chillers, cold storages, and other refrigeration equipment.

UniCool Monitoring

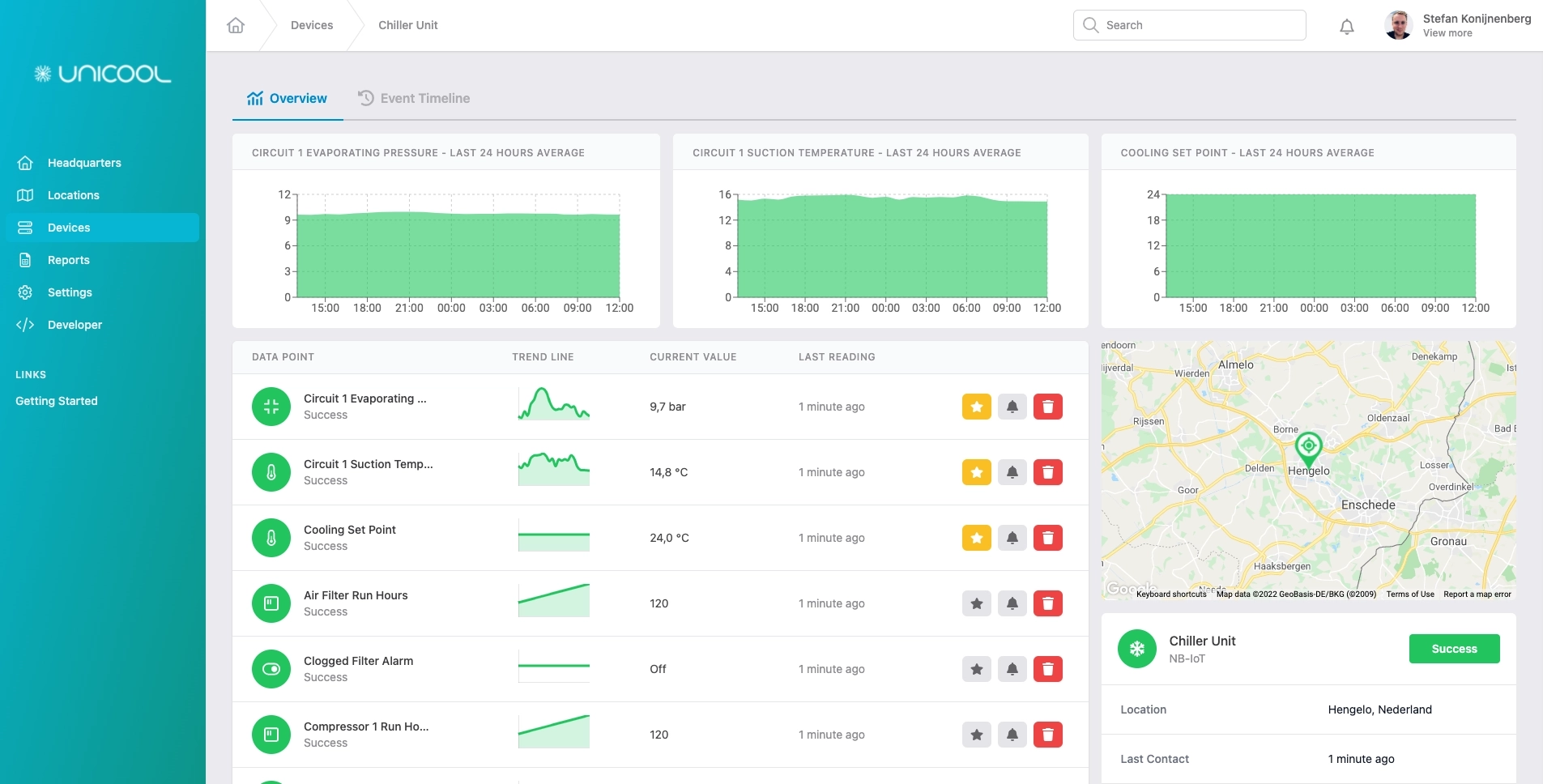

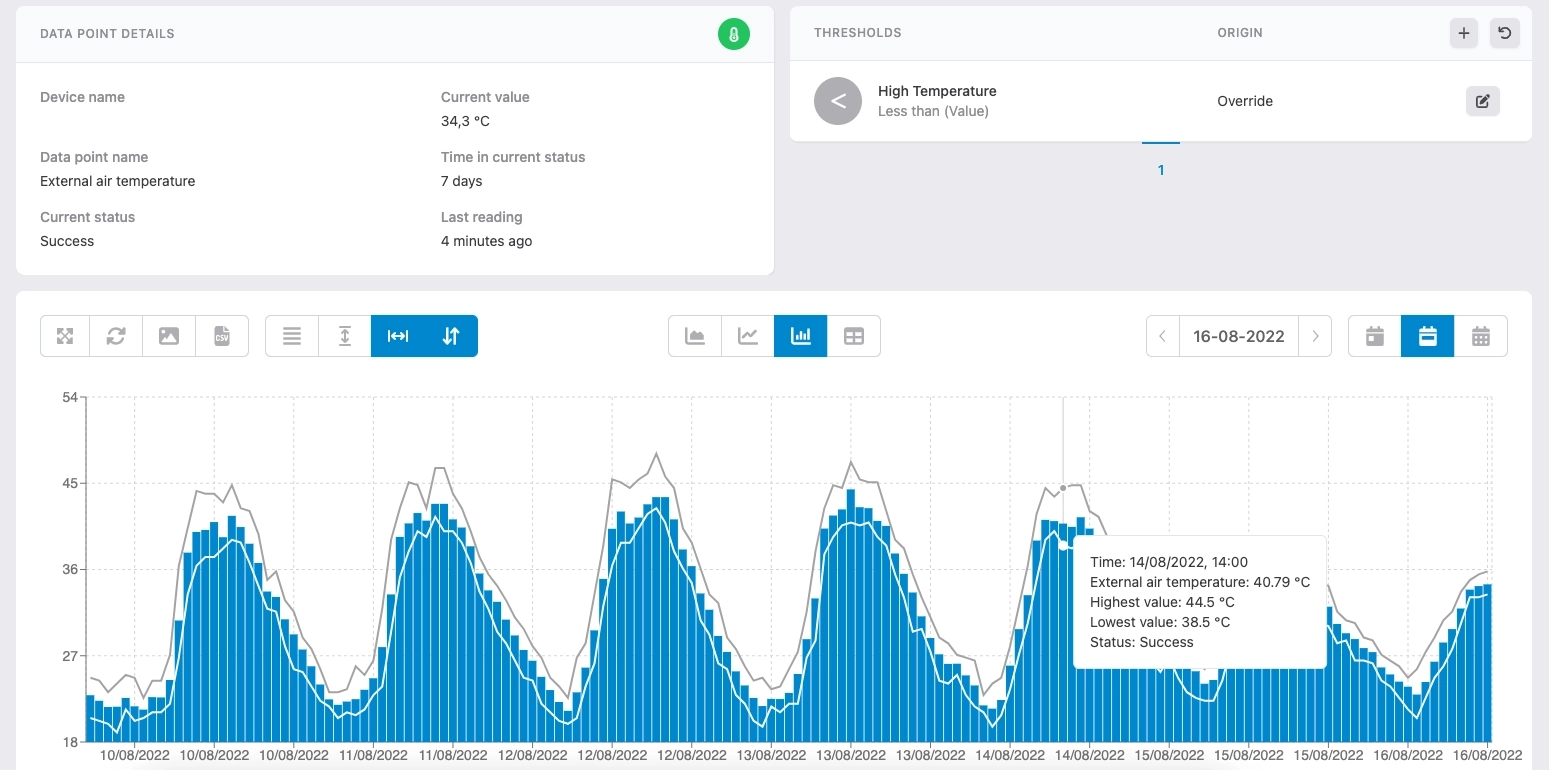

Using Docksters, UniCool is able to monitor all of the cooling machines they sell and service by installing small IoT gateways. This way they can be alerted if any monitored value is about to hit a threshold, or when errors occur. By constantly pulling all of the machine's critical information, UniCool is able to spot trends in the data, and perform (remote) predictive maintenance for each machine. This allows them to service their machines better, based on the needs of that specific cooler.

“Using Docksters, we can take our maintenance & service contracts to the next level.”

Data collection

Data acquisition, data visualisation and alerting are all parts of UniCool's solution and aim to improve productivity and save costs. Industry 4.0 not only facilitates data acquisition, it also paves the way for predictive maintenance. The UniCool IoT gateways are pre-configured and tested, so there are no tricky installation procedures to run through. Simply connect your cooling equipment to any network, and you are able to connect to your machines wherever they are in the world. In short, it is plug and play at it's best.

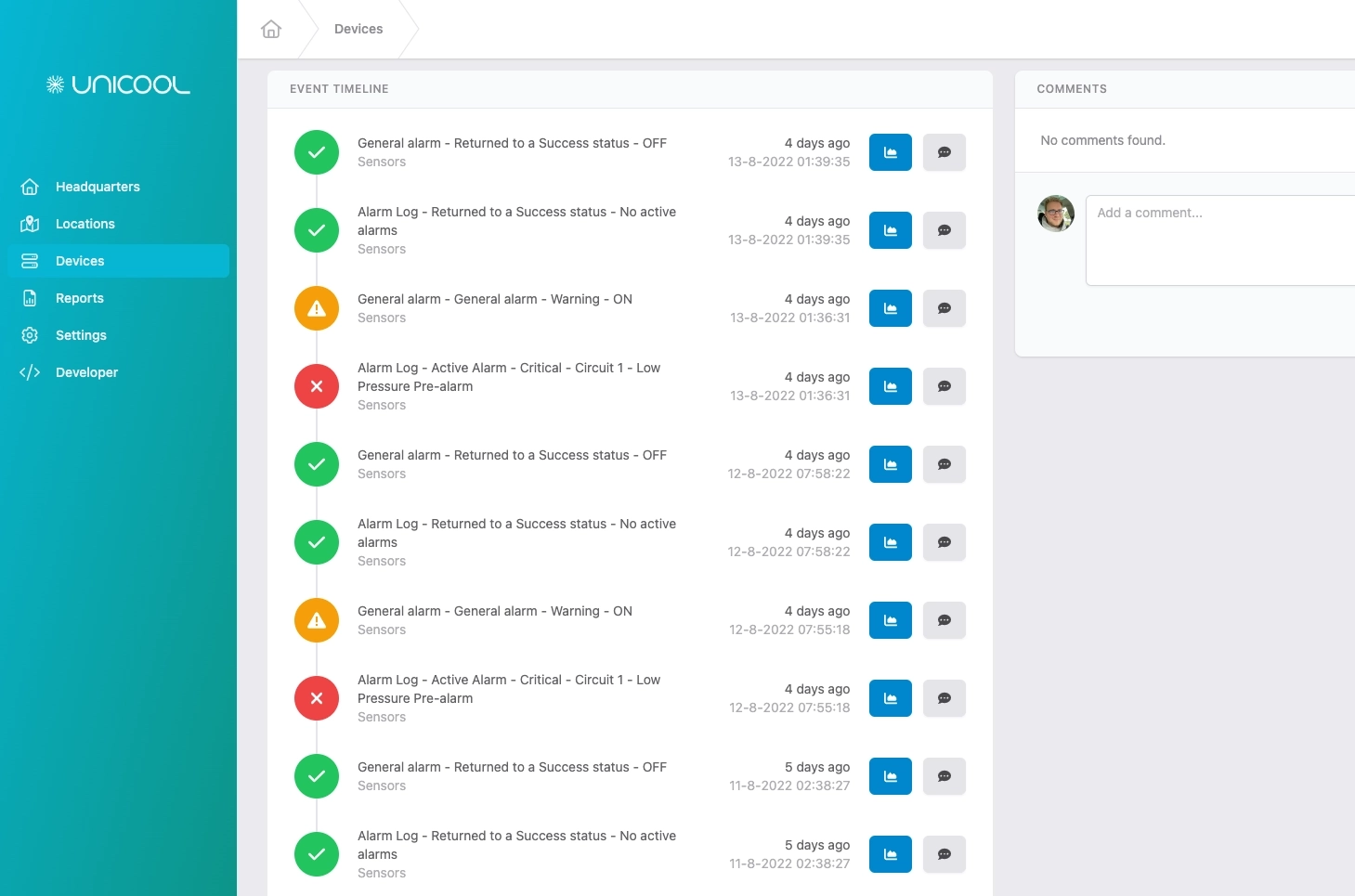

Stay informed

By collecting real-time information from the cooling equipment we can set a threshold on key measurement values. This ensures that assigned persons are notified (via e-mail, SMS, push notification or voice calls) when a key value deviates from it's desired status. This makes it very easy to perform maintenance and to notify the customer of maintenance or a necessary repair. Through our event page you can also easily see when there has been an alarm and when maintenance has been performed.